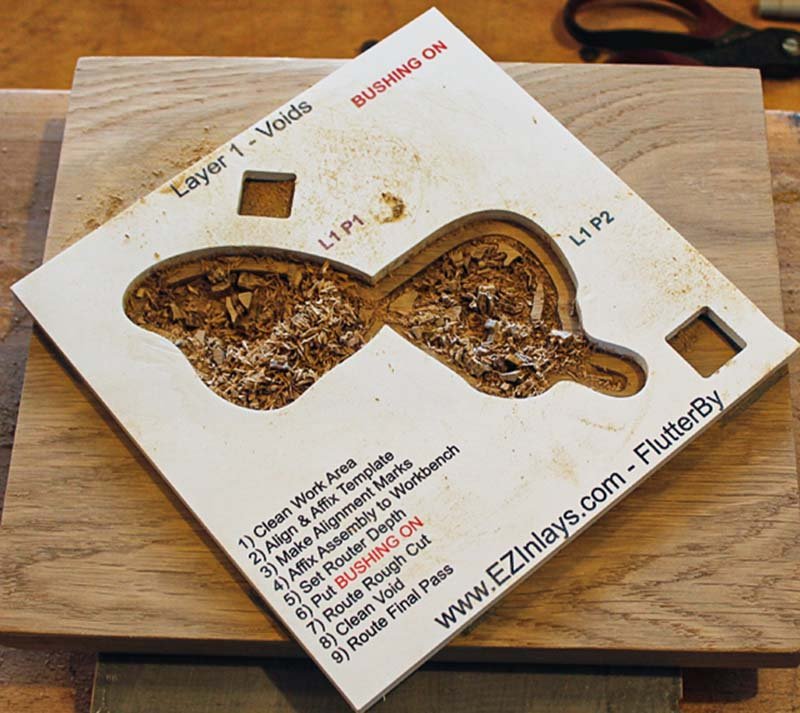

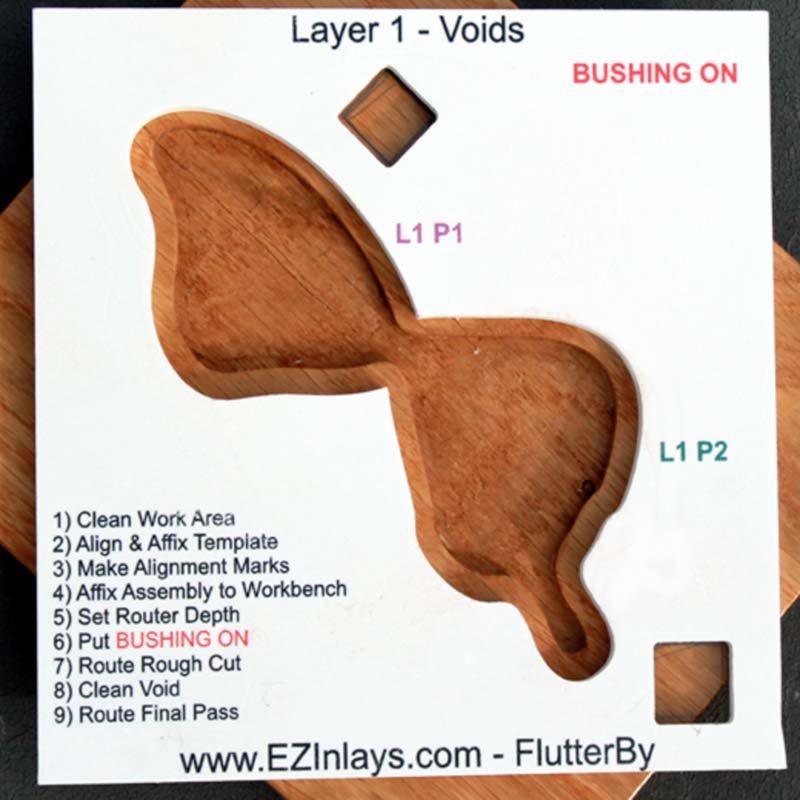

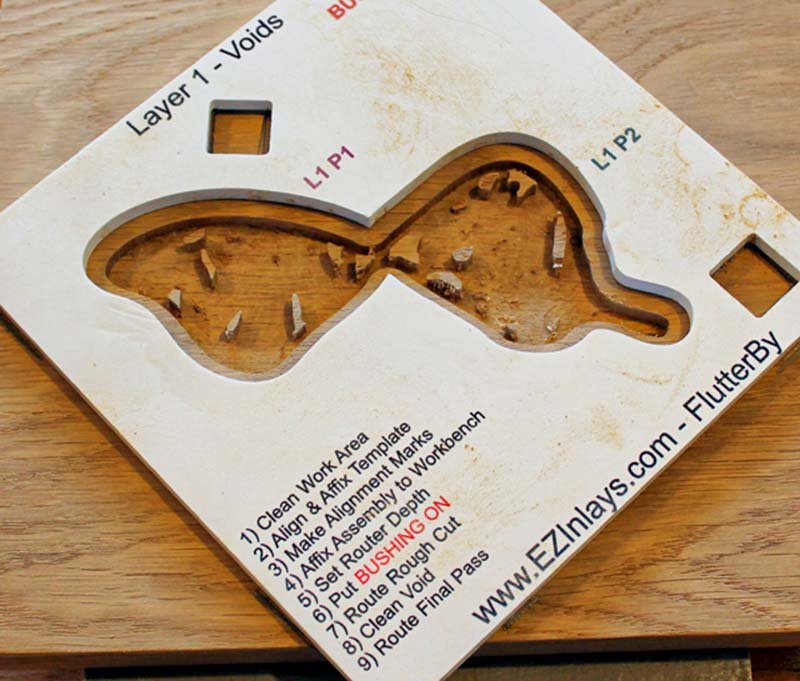

Bushing On

Set Plunge Depth

Setting up the Router

Any time you're cutting a void put the BUSHING ON the brass inlay kit. When putting on the bushing make sure you hear or feel it click into place.

Follow your routers procedures for setting the depth of plunge. Basically you want to create a pocket that is just about as deep as the thickness of the inlay material WITHOUT cutting all the way through the base material.

Turn the plunge router upside down, place a template on the base of the router, and then put a piece of wood that is as thick as the inlay material on the template. If you run your finger across of the inlay material you should not feel the router bit. If you can feel it decrease the depth of plunge.

You want your pocket to be slightly shallower that the inlay piece being put into it. If the void is deeper than the inlay piece then you'll end up with a recess in your base material. When this happens the only fix is to sand the entire base material surface area until it's flat again. If the pocket isn't as deep as the inlay material is thick as the inlay piece then you have to sand the inlay piece down to the base material level. It's always better to sand the inlay piece down to the base material than the other way around!