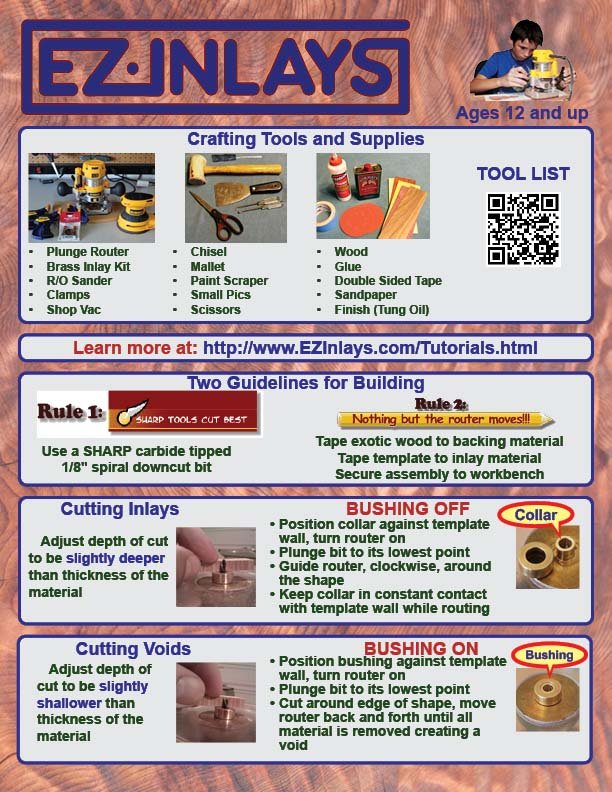

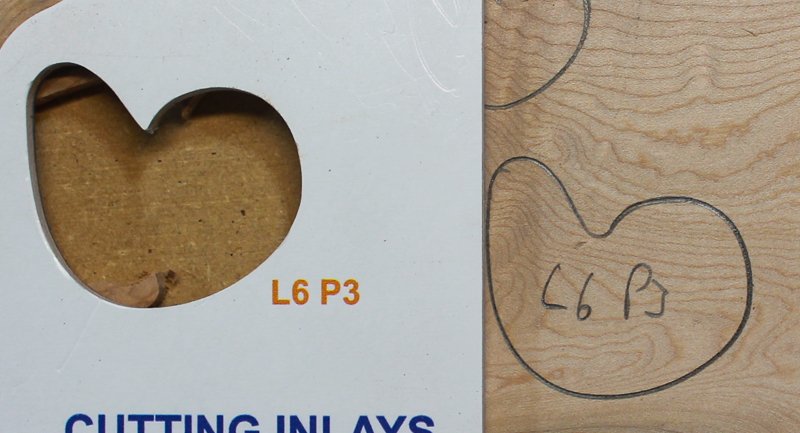

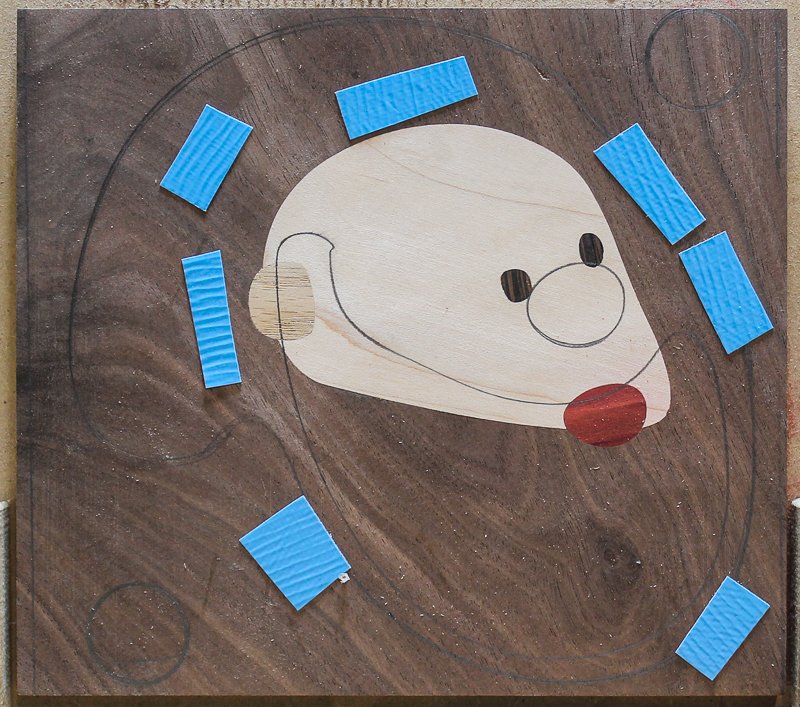

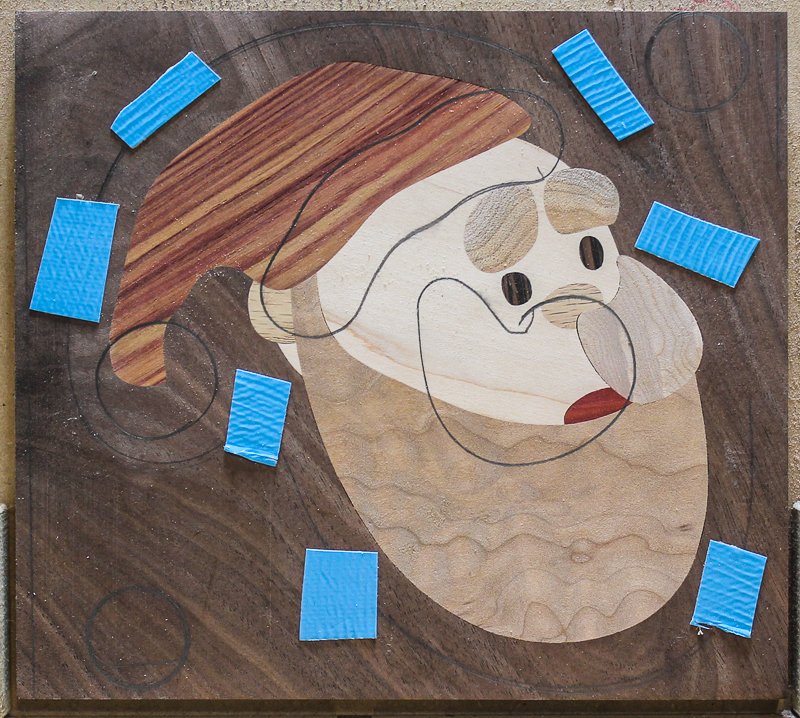

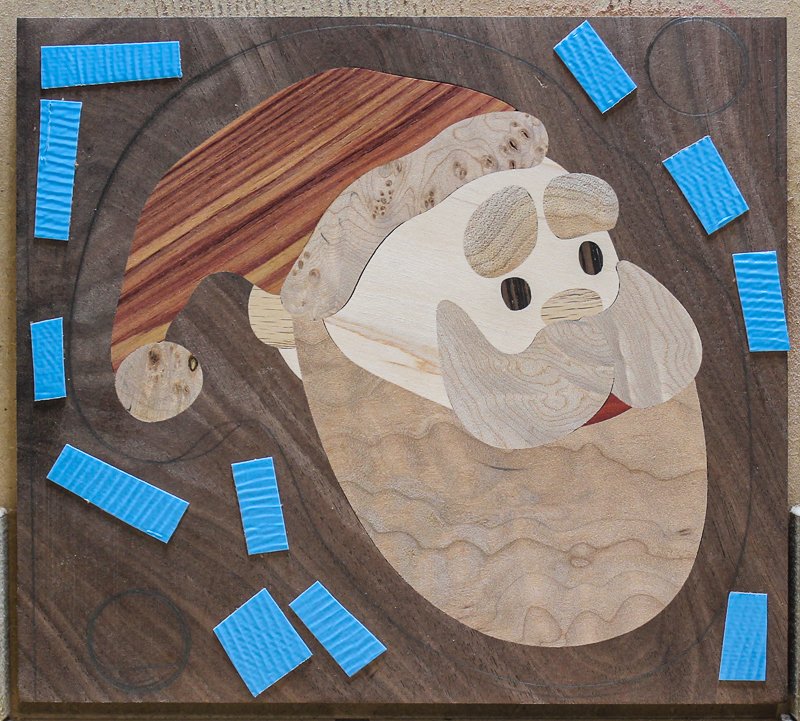

Select the Inlay Materials

This video explains the process used to select the inlay materials for this build of the decorative inlay Santa Christmas Ornament.

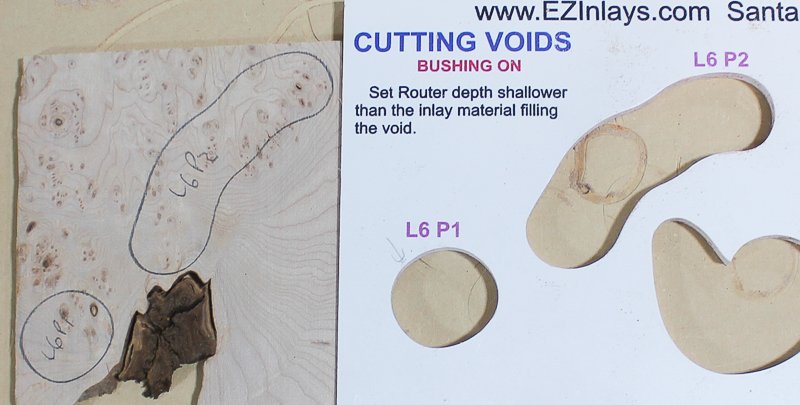

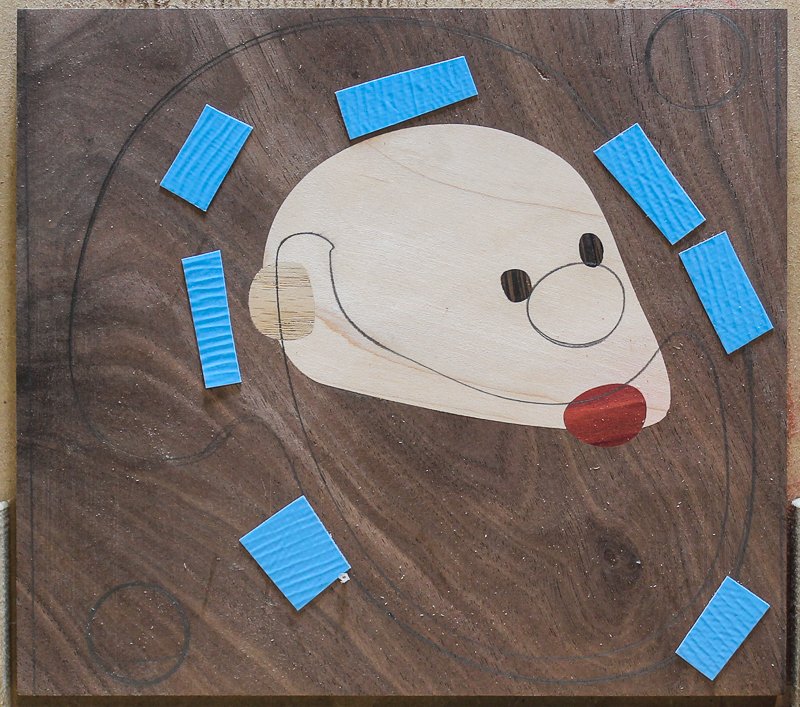

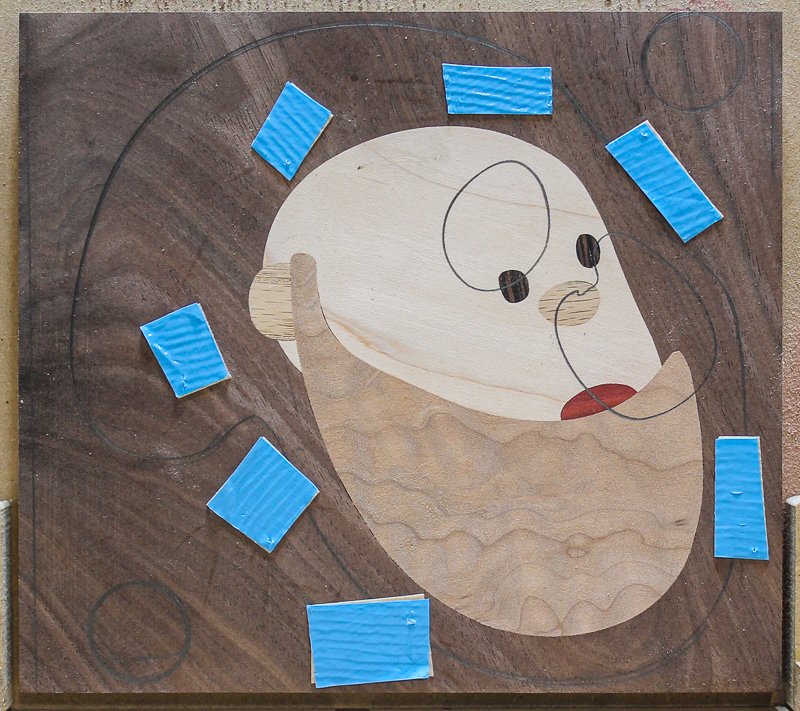

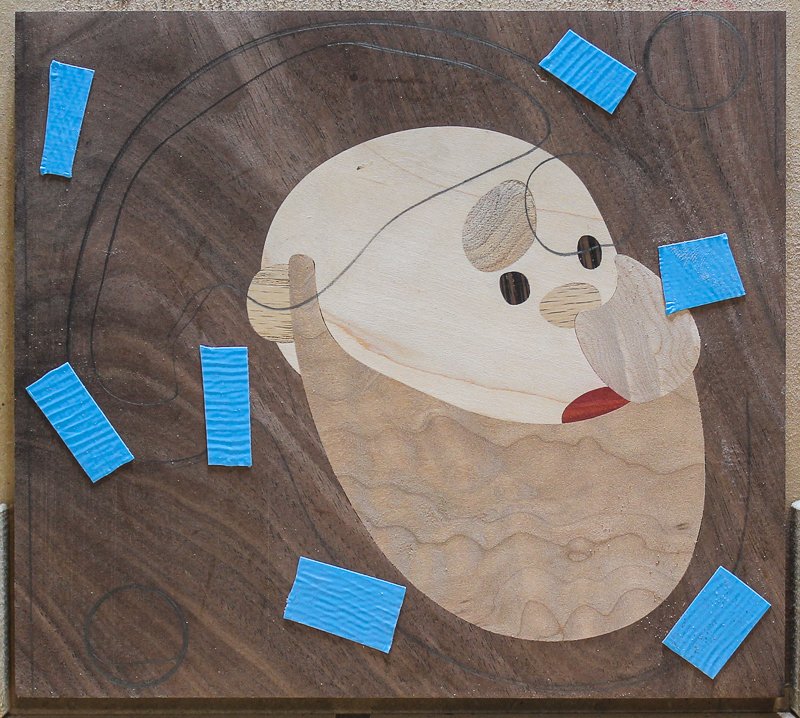

When selecting the inlay materials for Santa you'll want to focus on grain patterns, or a lack of for his face, and similar yet slightly different colored woods.

This design was created to honor childhood memories of the claymation Christmas special: Rudolph the Red Nosed Reindeer. Always makes me smile when I watch that show! :)

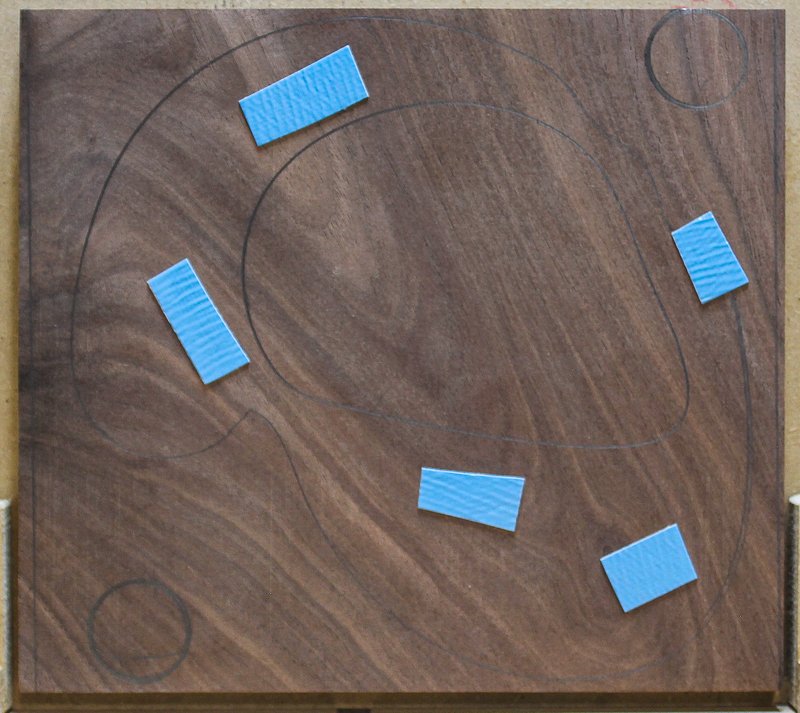

INLAY MATERIALS THIS BUILD

* Walnut 7" x 7" x 5/8" - Base material

* Pine 4" x 4" x 1/8" - Face

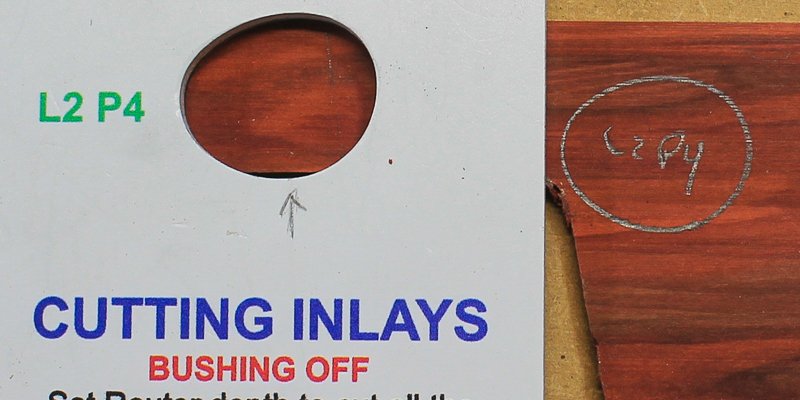

* Rosewood 6" x 3" x 1/8" - Santa's Hat

* Birds Eye Maple 4" x 3" x 1/8" - Fur on Santa's hat

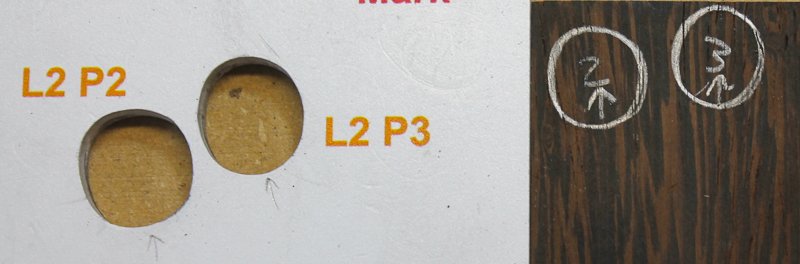

* Wenge 3" x 3" x 1/8" - Eyes

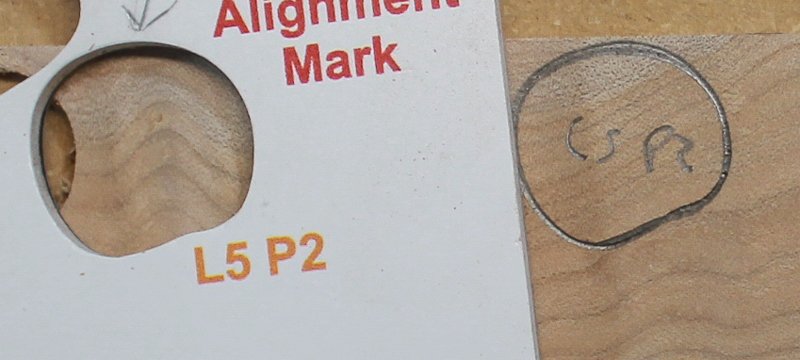

* Oak 3" x 3" x 1/8" - Nose and Ear

* Red Heart 3" x 3" x 1/8" - Mouth

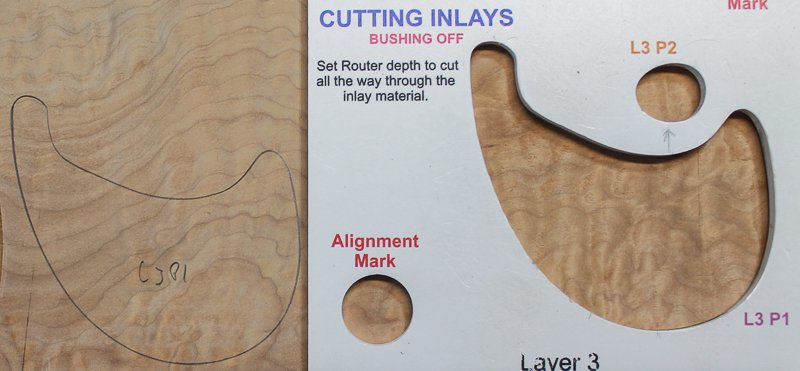

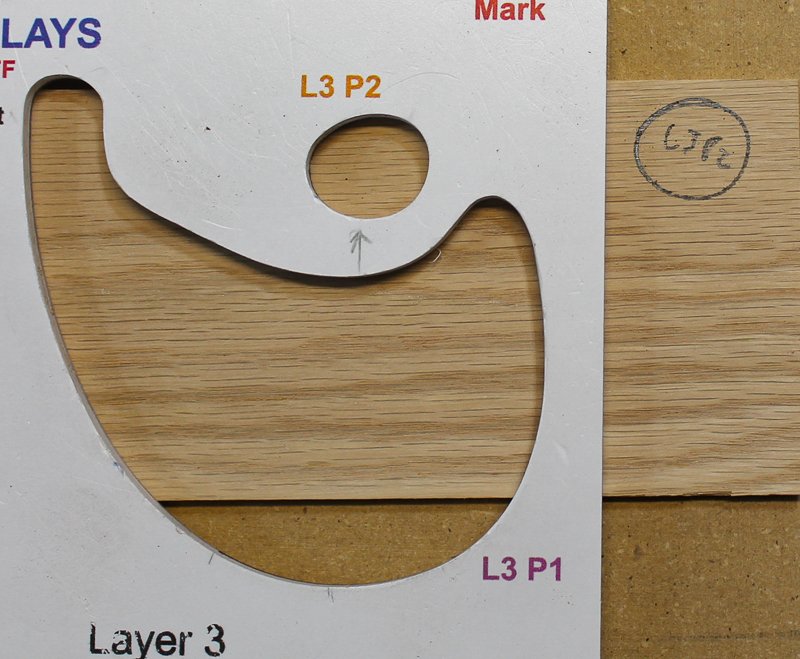

* Quilted Maple 4" x 5" x 1/8" - Beard and Eyebrows

* Figured Maple 3" x 3" x 1/8" - Mustache

GENERAL GUIDELNES

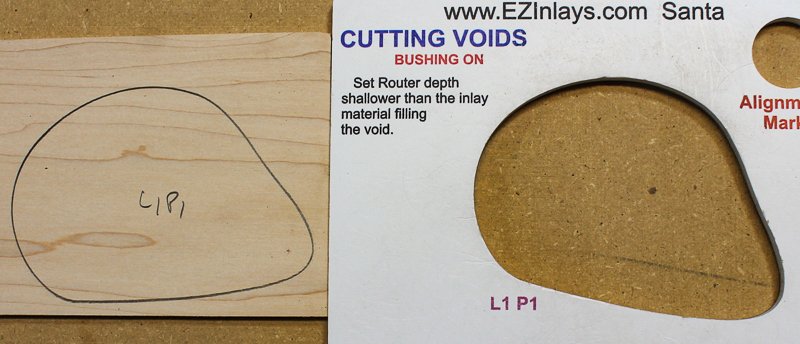

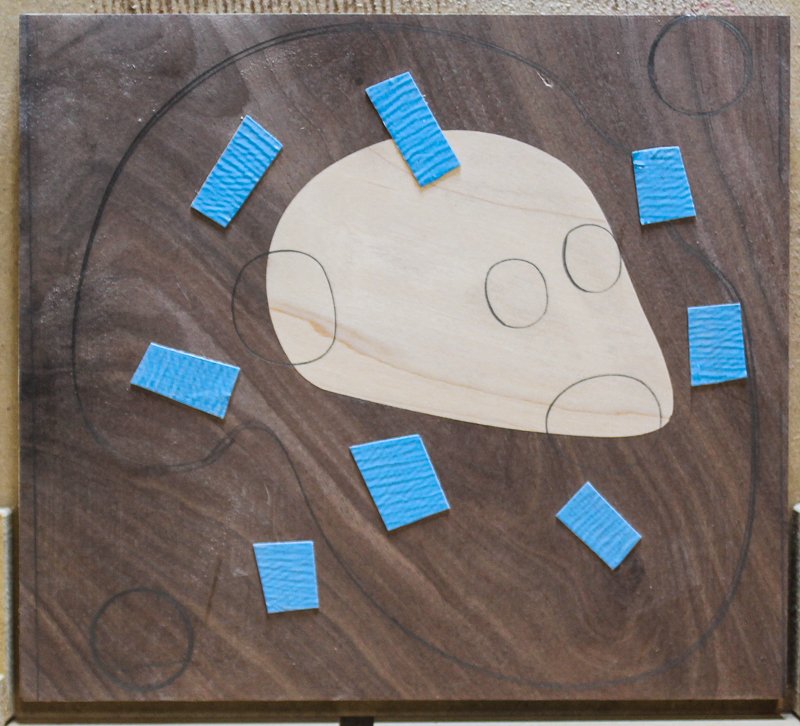

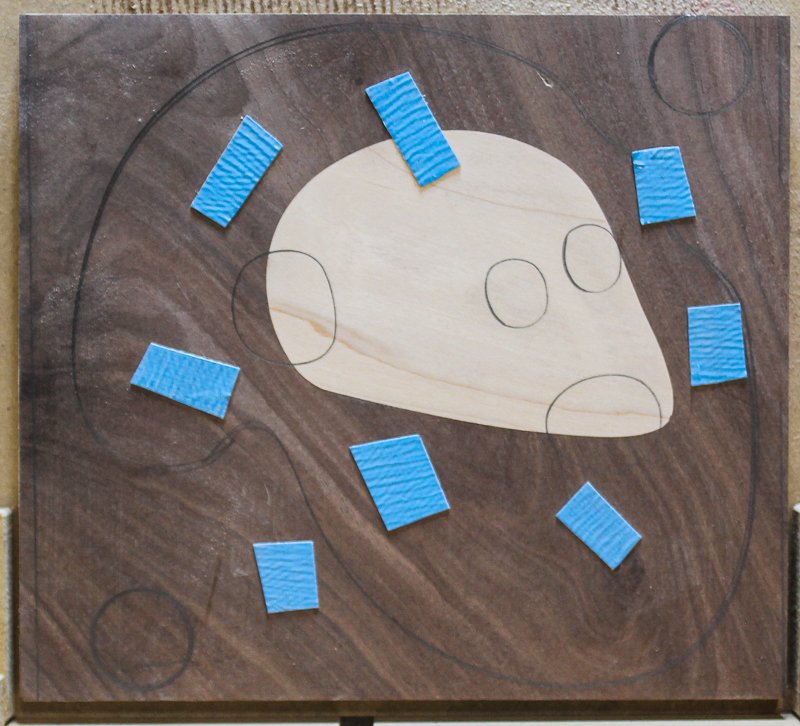

In this build four different types of woods that all had a similar color were used. The beard and mustache had to be made from different materials or else they

would have blended together. It's the same story for Santa's nose and ear. You'll need a color similar to the face but different enough to show contrast.

The eyebrows came from the same piece of wood that the beard came from, just a different area of the board that was different from the beard but still worked great for eyebrows.

$75

$75