$50

$50FREE SHIPPING

We only ship in the US

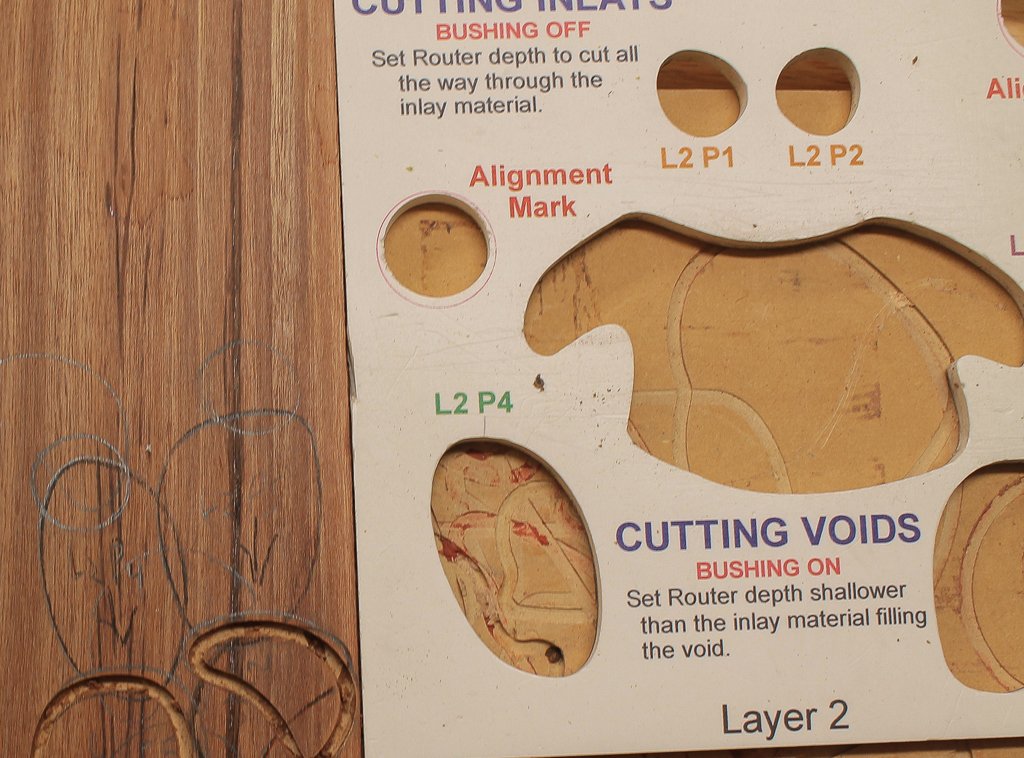

Dimensions: 6" Tall, 5-1/2" Wide

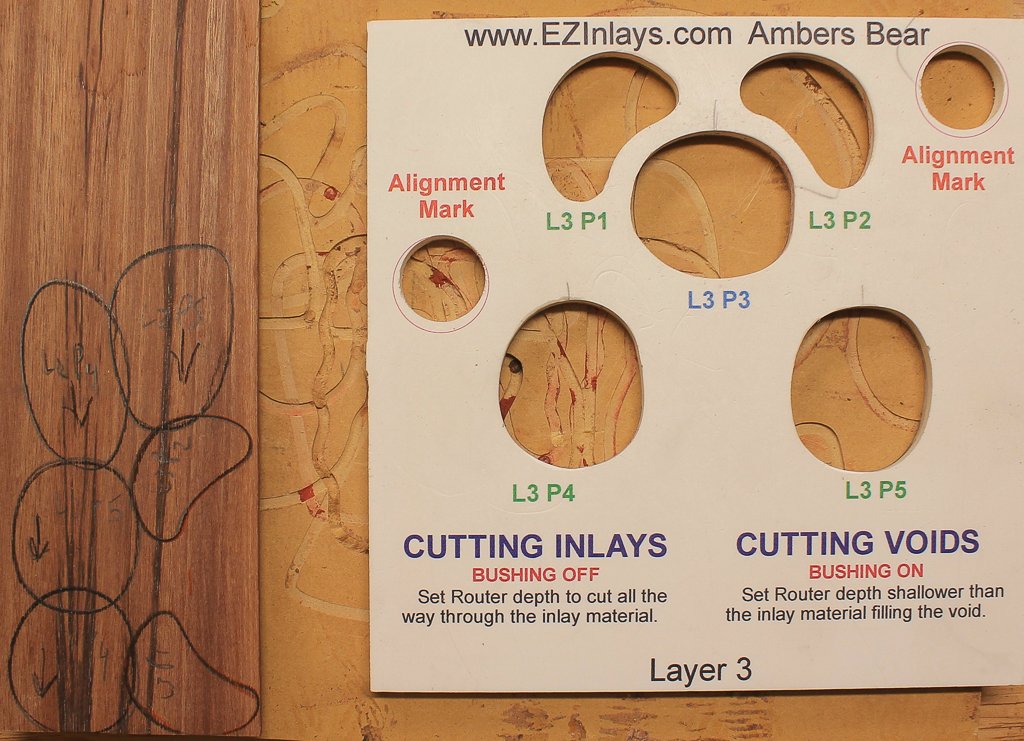

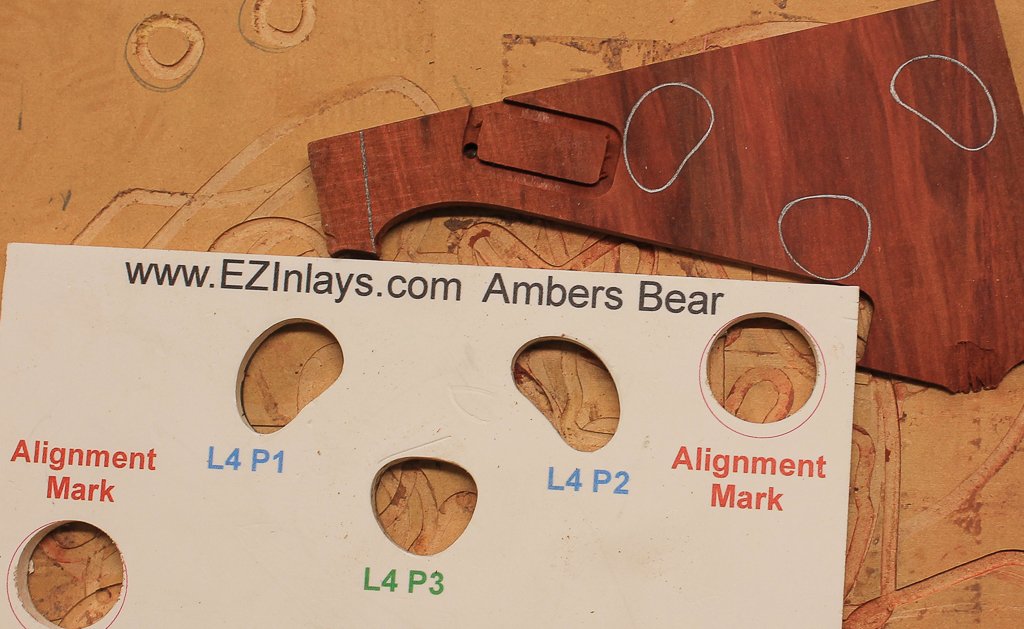

By following router based inlay techniques you're guaranteed to build an inlay that looks like something only the highest skilled craftspersons could make.

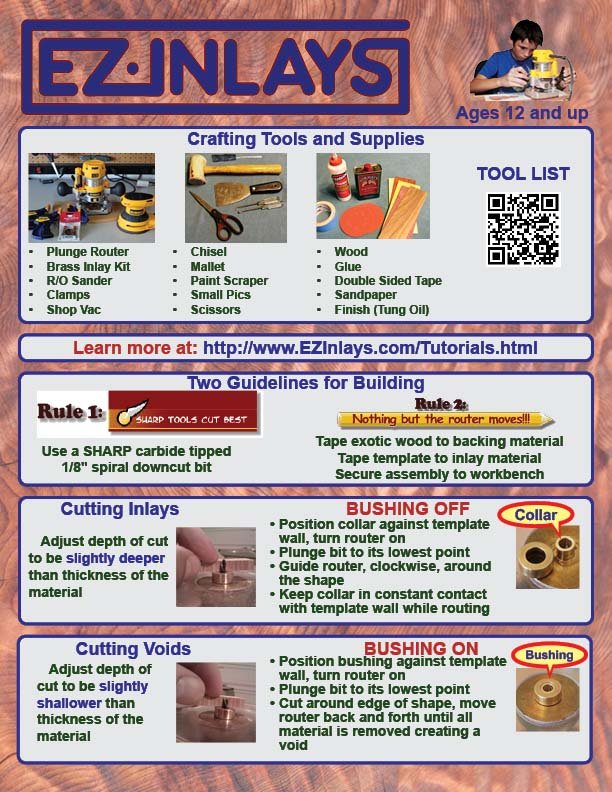

Best of all you don't need to be a master crafts-person, much less a woodworker, to build this inlay. All you need is a few basic tools that are inexpensive as well as safe and easy to use. Click here review the Router Based Inlay Tool List.

Never built an inlay before? Click here to Learn How To Build Any Wood Inlay.